- Supports

- About

-

News and Events

News and Events

Events

How can we help?

The World Class Manufacturing programme at Chrysler, Fiat & Co.

27th

October 2023

By Torbjørn H. Netland

The company-specific production system (XPS) of Chrysler is the World Class Manufacturing (WCM) concept, developed by the Fiat Group in 2006. But, what exactly is the WCM? And, what does Chrysler see as keys to success in WCM?

A few answers are given these days at the 4th annual Lean Management Journal Conference in Birmingham, UK: in his morning keynote, Mauro Pino—Vice President for vehicle assembly operations and the Head of World Class Manufacturing in the Chrysler Group—explains how Chrysler “achieves manufacturing excellence across the globe”. Pino stresses that “WCM is how we do our business. Period.” The presentation reminds me of the WCM factories I visited in Brazil, Spain and Sweden last year, all of which confirmed that WCM can be a powerful improvement system—if implemented seriously. Let’s take a closer look at the concept of WCM.

The development of World Class Manufacturing

WCM was developed by Fiat and partnering firms in 2005. Hajime Yamashina, Professor Emeritus at Kyoto Universty in Japan, played a key role. (Note that the WCM concept of Fiat is not identical to Richard Schonberger’s famous book from 1986 with the same name). From the outset, all Fiat-group companies took part in the new journey towards operational excellence. Consequently, WCM was launched in Fiat’s automobile and powertrain divisions, in Maserati, in Lancia, in Alfa Romeo, and so on. The Fiat-owned companies CNH (manufacturer of Case agricultural equipment and New Holland tractors) and the truck- and engine manufacturer Iveco also use WCM as their XPS. In fact, today, companies as varied as the Royal Mail, Ariston (manufacturer of white goods), Unilever (consumer goods), Atlas Copco (industrial tools), Barilla (pasta) and 12 different transportation companies reportedly use the WCM concept.

The Chrysler Group joined the WCM when Fiat acquired majority shares in 2009 (as a consequence of the financial crisis driving Chrysler to bankruptcy). Today, Chrysler is known as the Comeback Kid. The incredible transformation is partly credited the WCM as a change programme. A stronghold of choosing WCM as an “off-the-shelf XPS” is that companies that join, get the benefit of a world class benchmark from the other participating companies. Today, 166 manufacturing plants in 16 countries are active partners in the worldwide WCM Association. 30 of these are Chrysler plants, whereas 45 belong to Fiat.

The content of World Class Manufacturing

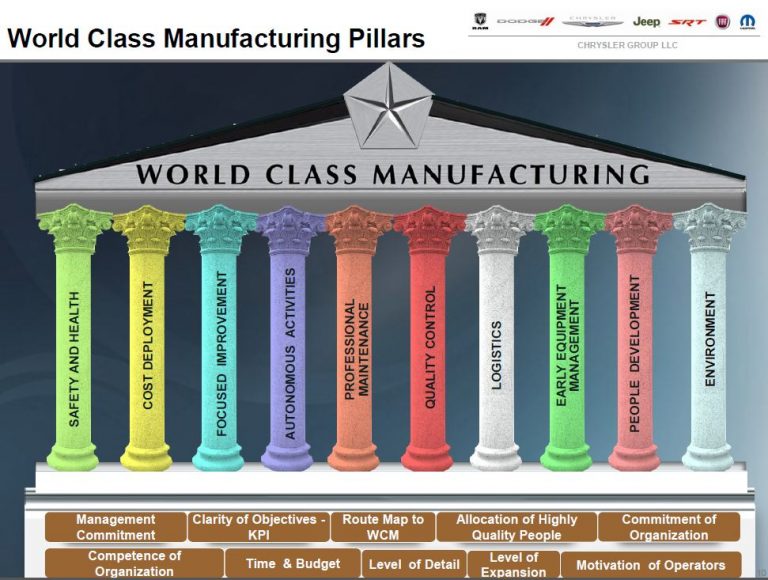

The WCM system is made up of ten technical- and ten managerial pillars, illustrated as a temple (see below). The ten technical pillars are as follows:

1) Safety (Occupational safety)

2) Cost Deployment (Distribution of Costs)

3) Focused Improvement

4a) Autonomous Maintenance

4b) Workplace Organization

5) Professional maintenance

6) Quality Control

7) Logistics & Customer Service

8) Early equipment Management

9) People Development

10) Environment (and Energy)

And the ten managerial pillars are:

1) Management Commitment

2) Clarity of Objectives

3) Route map to WCM

4) Allocation of Highly Qualified People to Model Areas

5) Commitment of the Organization

6) Competence of Organization towards Improvement

7) Time and Budget

8) Level of Detail

9) Level of Expansion

10) Motivation of Operators

Key characteristics of the World Class Manufacturing concept

The Cost Deployment pillar is of particular interest because it differs from the typical XPS (see this post to learn what is “typical”). Cost Deployment is a seven-step accounting technique for assigning actual costs to each loss and waste that happens in a factory. This way, the prioritization of which loss to attack first can be made with economical reasoning. An additional advantage of Cost Deployment is that all improvement work in the organization is assigned an equivalent saving potential. This motivates further improvements, and is the best argument for convincing remaining skeptics and cynics. To do proper Cost Deployment you need to team up persons from accounting, finance and operations.

Another key characteristic of the WCM concept, is that change always starts with a model area. The model areas are pilots for the implementation of the principles. For example, the plant typically chooses the worst performing machine as a model machine for the Autonomous Maintenance pillar. Through a dedicated project, using WCM tools and techniques, this model machine is “brought back to basic condition” and made the best performing machine in the plant. The learning points and good practices are thereafter shared with the rest of the plant. This is however a challenging way to implement an XPS; you risk making “islands of excellence” that do little good for the overall performance of the plant. I guess that’s where cost deployment comes in again and ensures that practices are spread.

A third interesting notion in WCM, is the “concept of zero“. A manager in Brazil explained me: “You can’t discuss with zero; once you suggest another target, you’ll get into all kinds of unfruitful discussions”. The target of WCM is zero waste, zero defects, zero breakdowns and zero inventory. The model areas should prove achievement of zero for several weeks before solutions are spread.

For Chrysler, the latest WCM strategy is a strong focus on education. For that purpose Chrysler has built a World Class Manufacturing Academy (WCMA) in Warren, Michigan. The WCMA is a state-of-the-art training centre for all employees in Chrysler, making use of modern technology and the latest knowledge on practical training. Because 70 % of Chrysler’s work force work in fair proximity to the Academy, many plants can afford sending their employees to training in Warren. The idea is that the plants should use Cost Deployment to identify areas of improvements, and then send employees for specific training in needed tools and techniques—not just general training.

WCM is not a static never-changing improvement programme. In 2010, an Energy sub-pillar was introduced in the Environment pillar “to improve the ability to identify and implement measures to reduce waste and achieve greater energy efficiency”. Obviously, a production improvement programme can also contribute to greater good!

Are you interested in more information on corporate XPSs?

Check out posts about XPSs in general, the Honeywell Operation System, the Harley Davidson Operating System, or the Toyota Production System.

Further reading

- Selection of Professor Yamashina’s presentations on WCM at baidu.com (don’t mind the design, the content is the important thing)

- WCM briefly explained at Fiat’s homepage

- World Class Manufacturing is Chrysler’s Universal Language, Industry Week, Aug 15. 2012

- Information on the WCM Academy in Warren, MI

- Schonberger, R.T., 1986. World class manufacturing: the lessons of simplicity applied. ASQC Quality Press

- Netland, T.H., (2013). Exploring the phenomenon of company-specific Production Systems: One-best-way or own-best-way? International Journal of Production Research, Vol 51. Issue 4, pp. 1084-1097

- Roberto Priolo (2013) World class, the world over. Interview with Mauro Pino in the Lean Management Journal, Vol. 3,Iss. 2, p. 7-11

This article is written and reproduced with the kind permission by Dr. Torbjørn Netland who is a Tenure Track Assistant Professor and the Head of Chair of Production and Operations Management at the Department of Management, Technology, and Economics, ETH Zurich, Switzerland. You can access his latest content through his website or follow him on LinkedIn and Twitter.